Issue

Company uses compressors to supply compressed air throughout production facility. Whenever there was a leak in the airflow line, the compressor would run 24×7 and eventually overheat. Company had to replace the compressor 3 times. After the third time, Company installed fans in the Compressor Room to continually cool the compressors.

Solution

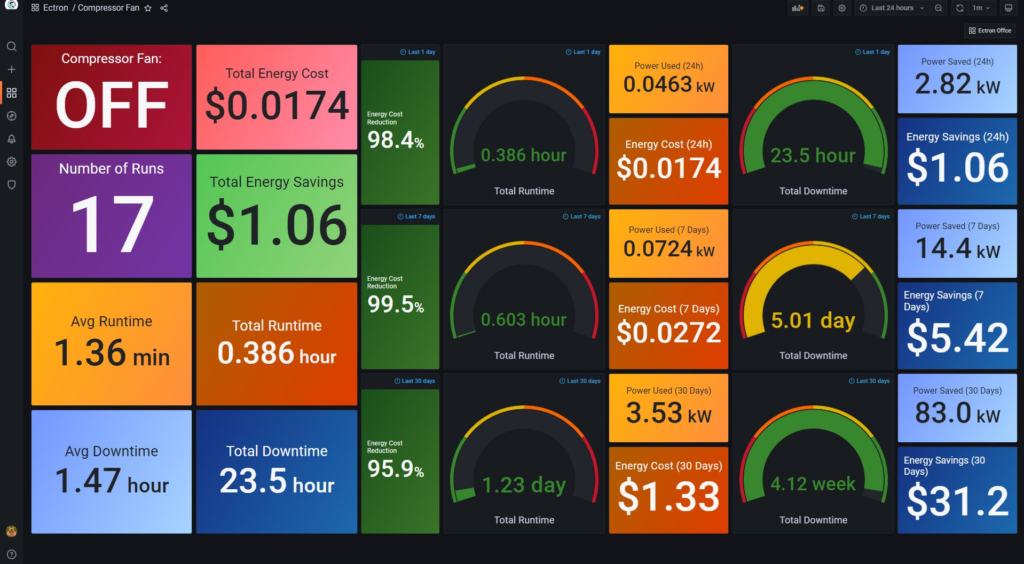

We instrumented the Compressor Room with environmental sensors. We also put a temperature monitor in the shell of the compressors. We also programmed SmartEYE™ to turn the fans on when the compressors heat up, and off when the temperature drops.

Outcome

If the Compressor and/or Compressor Room reach a certain temperature, then the fans are automatically started (without human intervention). Once the compressors cool down, the fans turn off. If the Compressor and/or Compressor Room stay at an elevated temperature, email and text alerts are sent to the Facilities Manager and Operations Manager.

ROI

Energy usage decreased 82% due to less compressor usage, as well as less fan usage. The compressor runs less because a simple leak in the line can be addressed quickly, as the data reveals the leak in real-time via elevated compressor temperature. Moreover, instead of the fans running all day, they only run when needed.