Smart Manufacturing / Industrial IoT (IIoT)

IoT projects are the heart of modern industrial transformation. Connecting devices, sensors, and plant control systems is critical for generating new data-based insights. While the benefits of IoT are numerous, IoT implementations are complex and can be very tedious. A variety of factors need to be taken into consideration when deploying IoT solutions.

Deployment considerations include decisions on the right technology platforms to connect sensors, edge devices, data transmission infrastructure, and cloud storage. Ensuring that the data from devices is aggregated at scale and archived appropriately for analytics is also crucial. Further, deciding the scope and frequency of the data collected is also important. All these considerations make technology and cross-domain expertise central to the success of IoT deployments.

In industrial and factory settings, the device infrastructure is heterogeneous and is a mix of modern devices and legacy devices that may not even be on TCP/IP connectivity. Unlike in other settings, disruptions or problems in the devices or network can have dire consequences for human safety and incur massive financial losses. IoT deployments need to not just manage a challenging device landscape but also ensure that operations continue without disruption.

Arrow and Ectron Solution for Smart Manufacturing

Arrow and Ectron Partnership

Ectron and Arrow executed a comprehensive plug-and-play industrial automation solution to enable the digital transformation of any factory into a smart factory. SmartEYE™ solution is an IIoT based factory 4.0 Paas (Platform as a Service) that provides a 360-degree view of any manufacturing line, cell, or an entire plant. By applying big data analytics and advanced sensing and control technologies to a wide range of manufacturing activities- the solution improves productivity, operational precision, facility performance, and energy efficiency in a wide range of industries.

Arrow Electronics was engaged by Ectron to provide an end-to-end technology stack that allows stakeholders to deploy smart manufacturing technologies with ease. Ectron devices and software were complemented by Arrow’s expertise in edge hardware, integration, and on-site deployment and support. Arrow’s global presence and partner ecosystem helped Ectron gain scale and support implementations of a ready-to deploy platform for customers.

Ectron’s SmartEYE™ solution enables the digitization of manufacturing helping plant managers transform and automate their factory floors by combining edge computing and sensing technologies with cloud analytics and cutting-edge AI/ML methodologies. Stakeholders can harness data and analytics on-the-edge on several hundred data points in real-time, to monitor machines, personnel, energy usage, and processes and make accurate and precise decisions that facilitate OPEX reduction and product improvement.

The solution was successfully deployed as a pilot project in a large pharmaceutical company to test medical assays for pathogen presence and moisture content. Sensors were deployed on the dryers to constantly track the moisture and humidity levels of the assays during the manufacturing process. Granular data on moisture and relative humidity levels were gathered and processed locally on edge computers and then sent to the cloud to run analytics on real-time data and historical data. The solution offered hierarchical easy-to-use BI dashboards at every level and afforded real-time and historical information to the end-user. Stakeholders harnessed data-based insights to streamline and optimize the production process to ensure consistent product quality.

The successful execution of this project demonstrates operational efficiencies that could be extended to other industries such as food processing and a wide range of other industrial settings.

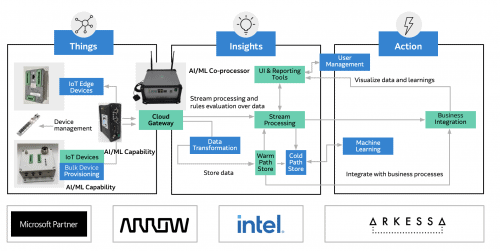

Solution Architecture

Solution Components

Ectron’s SmartEYE™ solution combines sensors, networking, cabling, and edge computers. Edge computers can connect to over 1000 different kinds of analog and digital sensors (magnetic, capacitive, optical, imaging/cameras, inductive) either through an OT network such as Ethernet IP or Profinet or through MTConnect on a machine. The plug-and-play customizable solution comes with pre-configured and pre-certified devices. Software to accelerate deployment in any industrial setting and on existing equipment and processes is also offered. The Azure IoT certified family of edge computers, working with Microsoft Azure, provide edge and cloud analytics on data points in individual production units or entire plant-level operations.

Customized Hardware and Services to Complement Ectron’s Offerings

Arrow brings a broad portfolio of hardware, services, project management, and global scale to Ectron’s expertise to maximize business outcomes. From ensuring the right design trade-offs between cost and functionality to implementing field upgrades, a host of service mechanisms can help companies accomplish business objectives. Arrow has been building and integrating technology solutions for over 20 years — enabling our customers’ business growth by simplifying their technology experience. As a solution orchestrator, we support the full lifecycle — from ideation, development, prototyping, and new product introduction (NPI) to manufacturing and global distribution.

Summary

Arrow and Ectron bring a comprehensive plant automation platform that aims to digitize any manufacturing environment to deliver real-time business and operational intelligence. The solution deploys edge computers, sensing hardware, and cloud analytics to derive real-time insights on critical production parameters. Many industries can optimize operations and realize large gains in energy efficiency, quality control, and operational cost savings.

To learn more about how Ectron can help you digitize your manufacturing environment, contact us today.